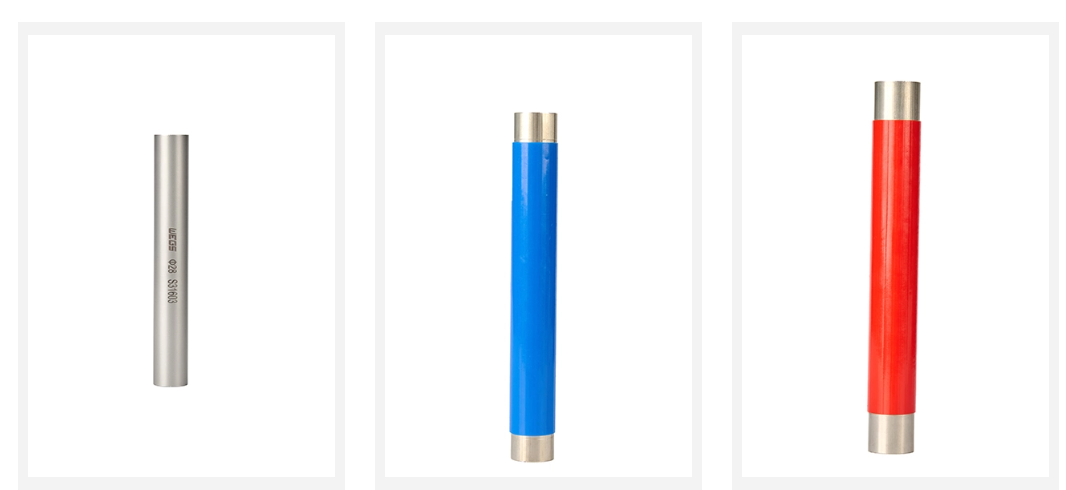

Material Aspect: Stainless steel pipes are alloys composed of metals such as iron, chromium, and nickel. The combination of these metals endows stainless steel pipes with unique physical and chemical properties. Copper pipes, on the other hand, are primarily made of pure copper, a metal known for its excellent electrical and thermal conductivity.

Corrosion Resistance: Stainless steel pipes demonstrate excellent corrosion resistance in a variety of corrosive environments due to the formation of a dense oxide film from the chromium element they contain. In contrast, while copper pipes have good corrosion resistance in fresh water environments, their corrosion resistance is not as strong as stainless steel pipes in some corrosive chemicals.

Strength: Stainless steel pipes, due to their alloy structure, have high tensile strength and pressure resistance, allowing them to withstand high working pressures, making them widely used in high-pressure systems, for example, SS grooved pipe. Copper pipes, due to their metallic properties, have relatively lower strength and are typically suitable for low-pressure systems.

Thermal Conductivity: Copper pipes have a very high thermal conductivity, which makes them popular in applications that require rapid heat transfer, such as refrigeration systems and heat sinks. Stainless steel pipes have relatively lower thermal conductivity, making them less suitable than copper pipes in applications requiring efficient heat conduction.

Price: Stainless steel pipes are generally more economical in the market due to their relatively lower manufacturing costs. Copper pipes, due to the inherent value of copper metal and processing costs, are usually more expensive than stainless steel pipes.

Application Fields: Stainless steel pipes, because of their corrosion resistance and strength, are widely used in industries such as water supply, chemical, construction, automotive manufacturing, and food processing. Copper pipes, due to their excellent thermal conductivity, hold an irreplaceable position in fields like heating, refrigeration, and power transmission.

Different types of stainless steel tubes are widely used in various industries. 44mm stainless steel tube is often used in the fields of construction and decoration, and is favored for the excellent corrosion resistance and beautiful appearance. In the food processing and pharmaceutical industries, smaller diameter stainless steel tubes are used to transport liquids and gases to ensure hygiene and safety. The oil and gas industry prefers large diameter stainless steel tubes for high-pressure transportation and structural support. In the automotive manufacturing industry, stainless steel tubes are used in exhaust systems and structural components to provide durability and strength. Whether it is 44mm stainless steel tubes or other models, they can show excellent performance in different application scenarios.

Please note that the prices are indicative and can vary based on market conditions, supplier, and specific requirements.

| Material Type | Price per Meter (USD) | Key Features |

|---|---|---|

| 304 Stainless Steel | 15 | Good corrosion resistance, widely used |

| 316 Stainless Steel | 20 | Superior corrosion resistance, especially in marine environments |

| 316L Stainless Steel | 22 | Low carbon version of 316, better for welding |

| 2205 Duplex Stainless Steel | 30 | High strength, excellent corrosion resistance |

| 2507 Super Duplex Stainless Steel | 35 | Extremely high strength and corrosion resistance |

| 904L Stainless Steel | 40 | High alloy, excellent resistance to acid corrosion |

| Copper Pipes | 18 | Excellent thermal and electrical conductivity, good corrosion resistance |

This table provides a general comparison of the prices and key features of different types of stainless steel pipes and copper pipes. For precise pricing, it is recommended to contact suppliers directly.